Eye-Tracking Robotic Arm

University of Leicester - Bioengineering Group

- Joe Ahuja

- Ian Chapple

- Amy Lymn

- James Reuss

- Will Scott-Jackson

Contents

Introduction

Amy Lymn

- 62,000 people living in the UK have an amputated limb

- Every year 1,200 people become paralysed in the UK

Project Aims

- Design and build a robotic arm

- Build an eye tracker for use in controlling the arm

- Design and implement a control system that uses an Xbox Kinect and the eye-tracker to allow accurate control in moving objects to the users desired location

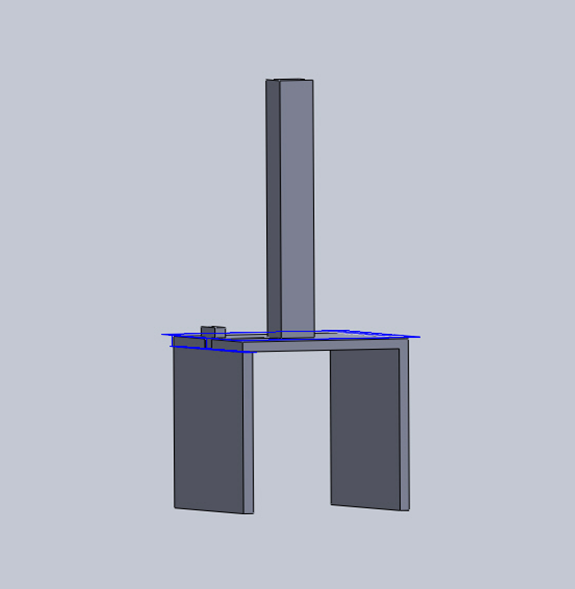

Mechanical Systems Design

Amy Lymn & Joe Ahuja

Mechanical Systems

- Rotational? Translational?

- Length?

- Load?

Concept Ideas

- Produce several concepts

- Assess each for feasibility

- Discount concepts that fall short

- Move one concept forward to be developed

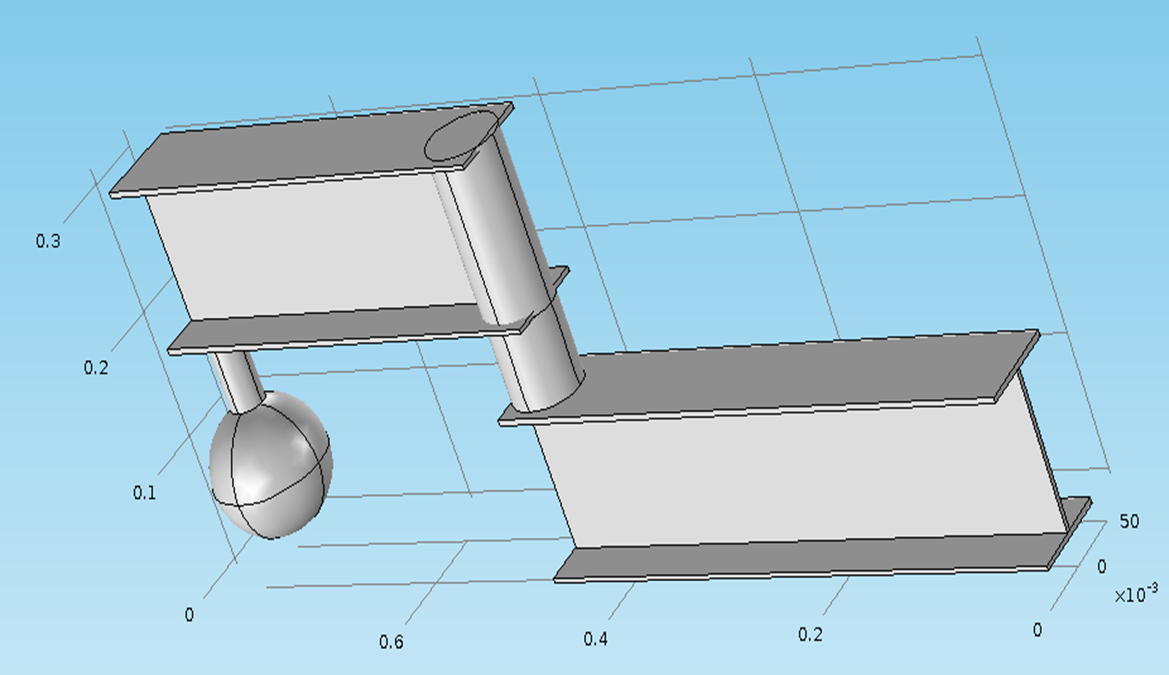

Concept 1

Measurements in metres

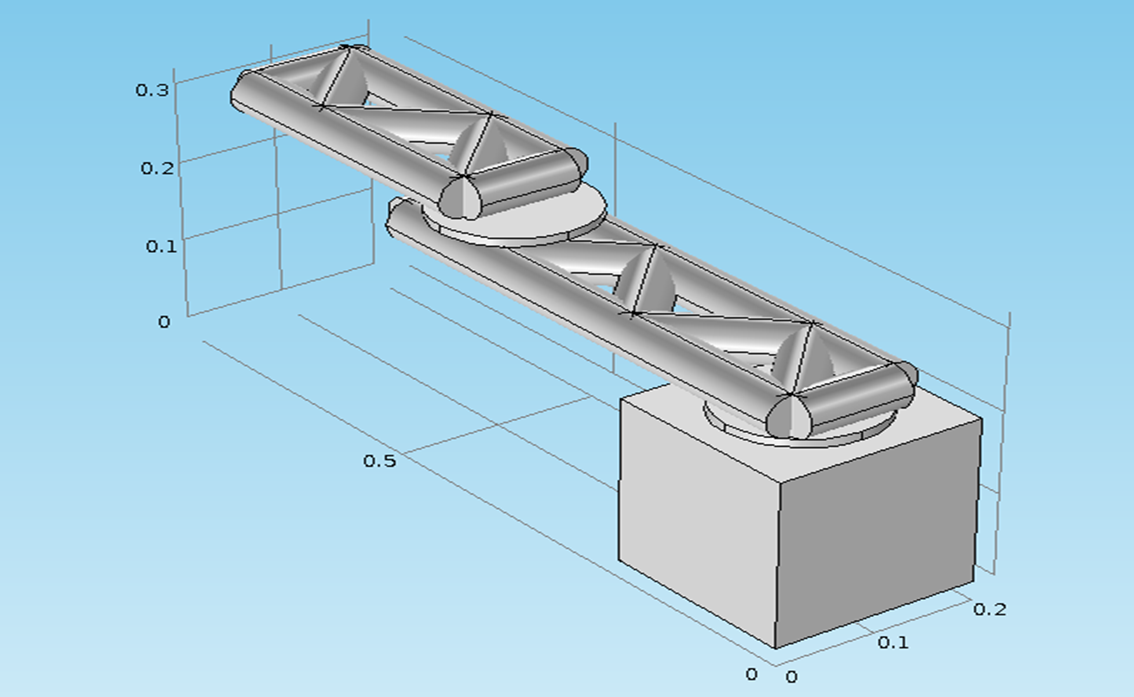

Concept 2

Measurements in metres

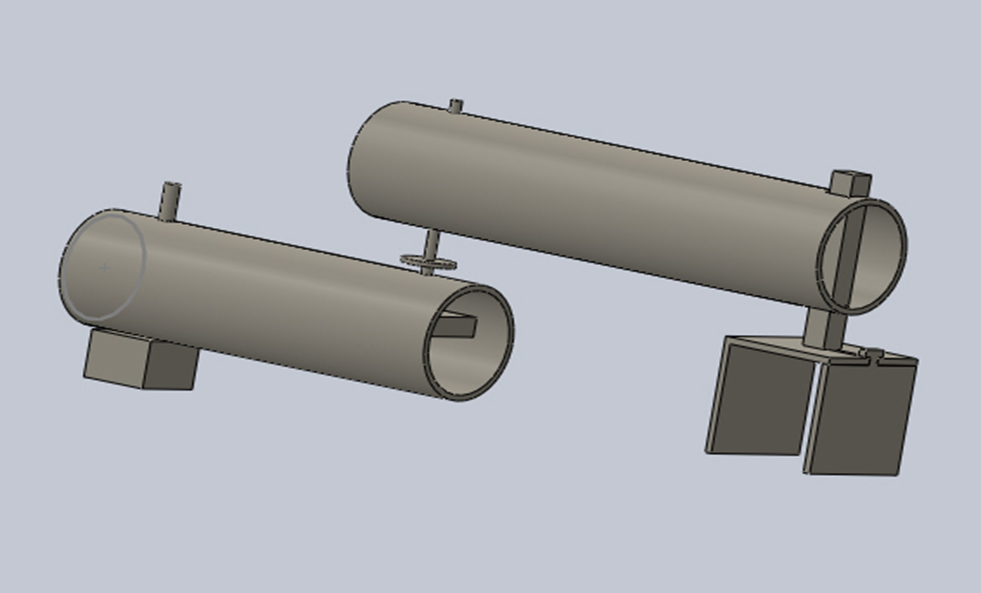

Concept 3

Grip Concepts

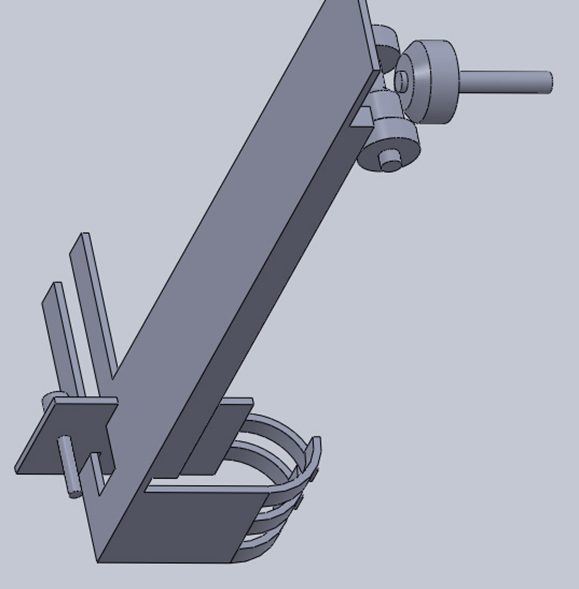

Development of Chosen Concept

- Develop concept with further design

- Manufacturing methods taken into account

- Expand design to include finer details

- Consider integration of drivers

- Consider linkages, fasteners etc

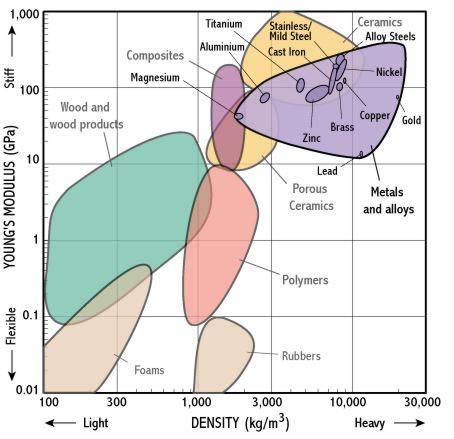

- Consider material limitations

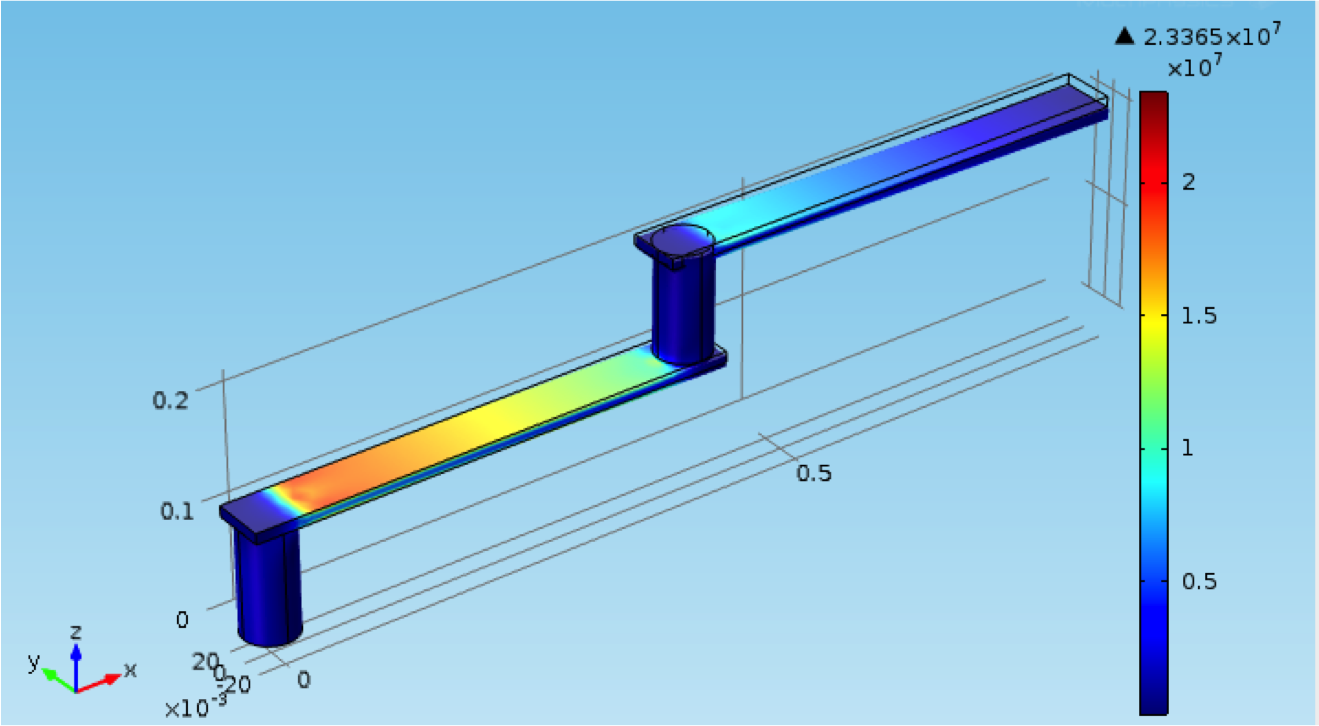

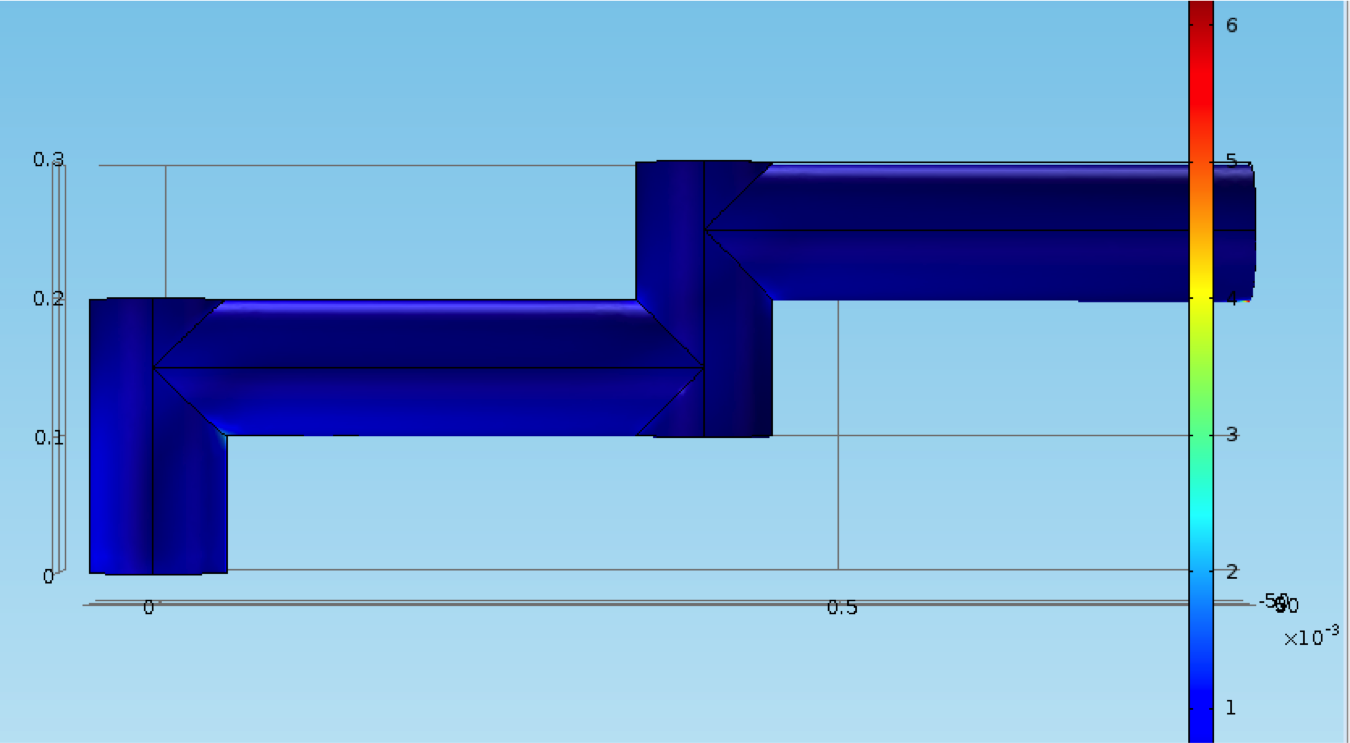

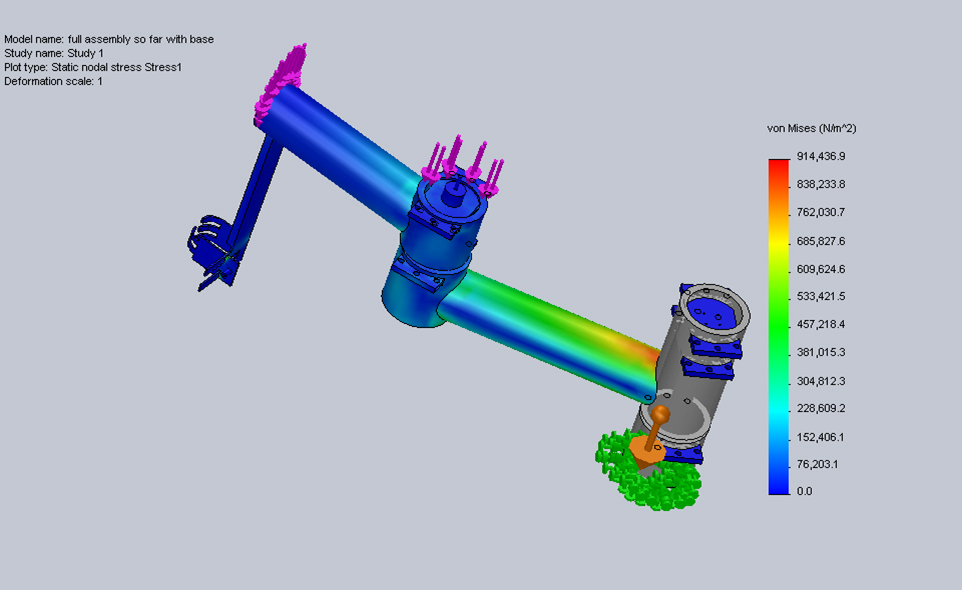

Detailed Mechanical Design

- Bring together material selection and developed concept

- All aspects of arm designed for manufacture

- Design simulated to provide accurate data

- Re-examine loads and stresses

- Consult workshop on ease of manufacture/cost

Full Technical Drawings

- Detailed design reproduced in technical drawings

- Drawings meticulously produced and checked

- All parts drawn individually

- All tolerances and materials added

- Submitted to workshop early December

Monitor Manufacture Process

- Make regular checks on manufacturing progress

- Deliver all ordered parts as they arrive

- Clarify drawings if needed

- Make suggestions/approve suggestions

Integration

- Work with other sub-teams on integration

- Provide them with needed data/dimensions

- Advise them on integration methods post manufacture

Testing

- Test arm as it is being manufactured

- Make any necessary changes from testing

- Industrial showcase provided good opportunity for demonstration

- Work closely with electrical sub-team to test and improve movement of arm

Limiting Factors

- Cost was a large limiting factor

- Rate of Manufacture limited full execution

Improvements

- More Degrees of freedom - versatility

- Re-design driver linkages - performance

- Better material quality - performance/versatility

- Better management of manufacture of design

Conclusions

- Cost effective, functional mechanical system has been designed

- System meets requirements

- System meets budget

- Designed within timescale

- Not fully manufactured within timescale

- Provides solution to original problem-proof of concept

- It is hoped this work can be taken on and improved in future

- Improvement and implementation could improve quality of life for users

Electronic Control System

By Will Scott-Jackson

Design Rationale

- To develop a proof of concept control system and driver systems that can interface with the Eye-Tracker and Object Detection

- To develop it so that it can operate as a standalone unit

- To develop the system using readily available, open source hardware and software

Breakdown of Sub-Systems

- Controller

- Power Supply

- Actuators and Drivers

- Feedback Control

- User Interface

Controller

A controller was required to implement the logic of the control system, it must:

- Be suitable for rapid prototyping of proof of concept software

- Be open source

- Have built in features such as analogue to digital converters and serial interfaces

- Be readily available at a reasonable price

Having considered the options, an Arduino Mega 2560 was selected:

This was selected because:

- It has many digital I/O pins

- 16 Analogue to Digital Converter pins

- USB port can interface with PC via serial link

- 16MHz of processing power

- Can be programmed with an Open Source IDE

Actuator Systems

Four electrical motors were required to drive the four degrees of freedom. There were several factors that needed to be considered:

- The various torque requirements/electrical power requirements

- Connecting to the driving mechanisms

- Controlling them with software/electronics

Actuator Systems (Research)

- Servo Motors

- Very high performance

- Built in feedback for control purposes

- Very expensive

- Difficult to implement in time given

- Stepper Motors

- Less expensive than servo motors

- Open loop control

- Easy to implement in both hardware and software

Actuator Systems (Research cont.)

- Iron Core DC Motors

- Very Cheap

- Very easy to implement

- No built in means of control however

Actuator Systems (Selections)

Based on the aforementioned research, several electrical motors were selected:

One Trinamic QSH-5718-51-28-101

One Astrosyn - MY3002 Size 11 Stepper Motor

Two RE 385 DC Motors

Actuator Systems Circuitry Development

In order to actuate these motors, specific driver circuity was required, although there were some factors to take into consideration:

- Electrical power requirements of the motors

- The stepper motor coil configurations

- Controlling the motors with software

- Standardising and Implementing on a PCB

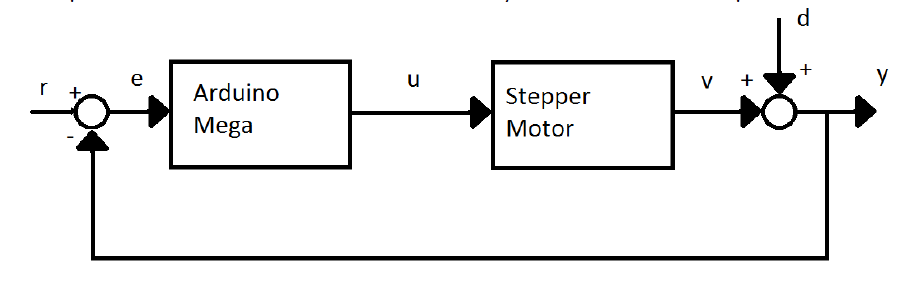

Feedback Systems

- Feedback control was required to improve overall system robustness

- Hall Effect Sensors used to provide positional information to the controller

- Sensor signals are compared with the input signals in order to make corrections

Feedback Systems (Implementation)

The feedback system corrects errors caused by disturbances caused by motor slip etc.

User Interface

In order to develop this system into a standalone unit, several major components were required:

- User inputs

- Buttons and switches

- Variable Inputs

- User feedback

- LEDs

- Liquid Crystal Display

Progress to Date

- Implemented initial prototypes of the aforementioned sub-systems but without extensive testing in-place

- Interface to Eye-Tracker/Object Detection hasn't been implemented

Problems and Limitations

- Stepper motors require gearing

- Resolution of feedback system is low

- Feedback system implemented for shoulder motor only

- Doesn't behave as a hard real time system

Further Improvements

- Unified Power Supply

- Replace stepper motors with servo motors

- High resolution Rotary encoders for feedback

- Improvements to software using TTC or Pre-emptive scheduling systems (i.e. real time)

- Implementation using real time microcontrollers

- Implementation of a Controller Area Network

- Alternative manual control schemes

Electronic Control System

Live Demo

Control Systems

Eye-Tracker

By Ian Chapple

Hardware

- Build a cheap eye tracker

- Normally cost >£10,000

- Built for ~£70 using:

- Playstation Eye Camera

- Infra Red LED's

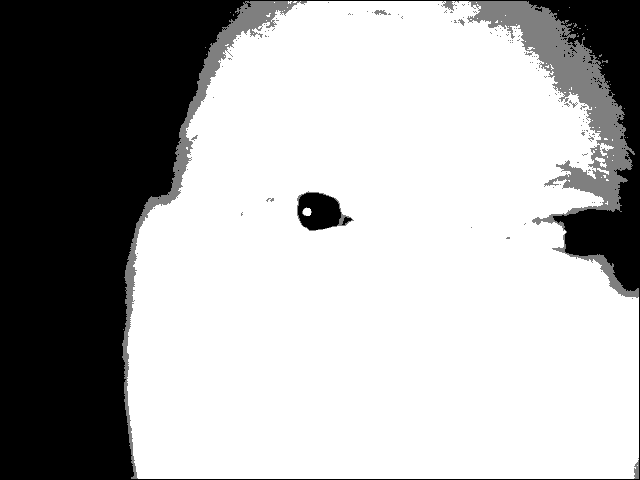

Software

Image Processing:

- Locate Eye/Pupil

- Locate glint from light source

Data Mapping:

- Map Data

- Find Coordinate from map and Eye/Glint locations

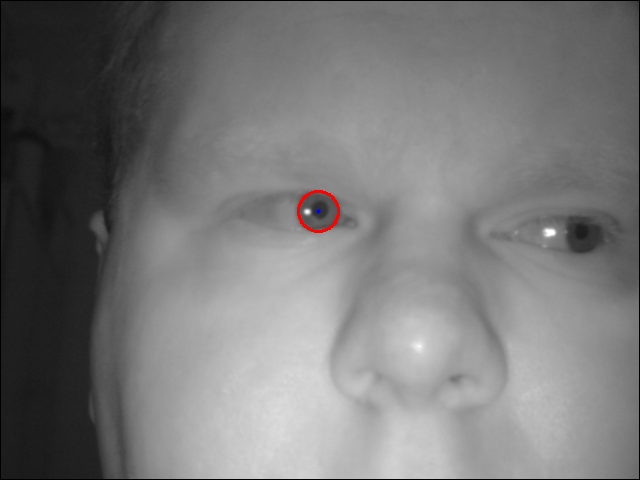

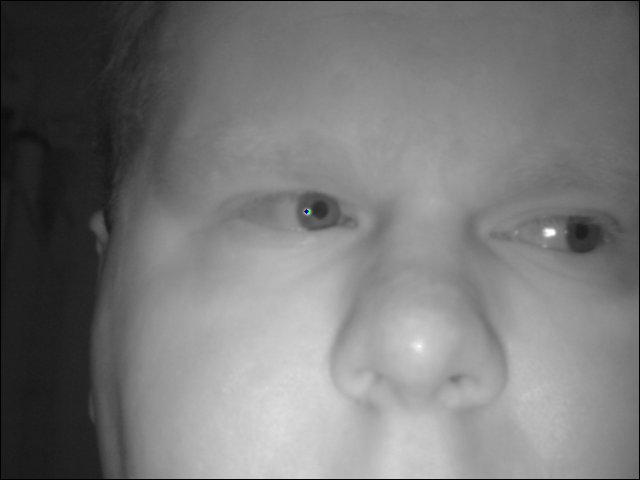

Contour Finding

Find the edges of objects in an image

Circle Finding

Locate circular objects from within an image

Glint Finding

Find brightest point in image

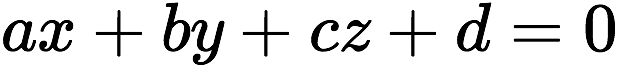

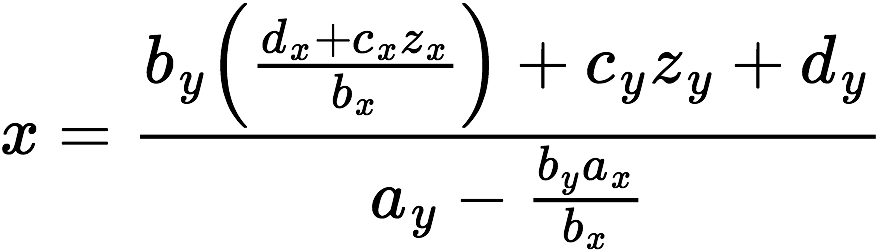

Data Mapping

Linear 3D map:

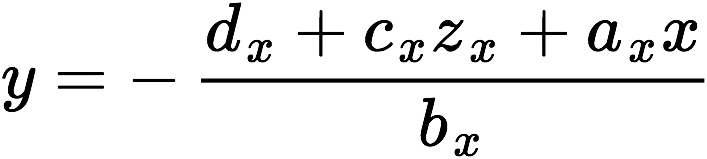

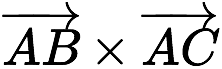

Use 2 sets of equations to locate coorinates (x,y):

Eye-Tracking

Video

Control

Object Detection

By James Reuss

Why is Object Detection Needed?

Because the system is unable to detect its environment!

How can this help?

- Determine if the user is looking at an object

- Determine alternate routes to avoid objects

- Aid in self calibration of arm position

What's the Problem?

All of these systems are expensive!

The Kinect

- Released in 2010 by Microsoft

- Costing around £100

How does the Kinect work?

Pixel Organisation

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

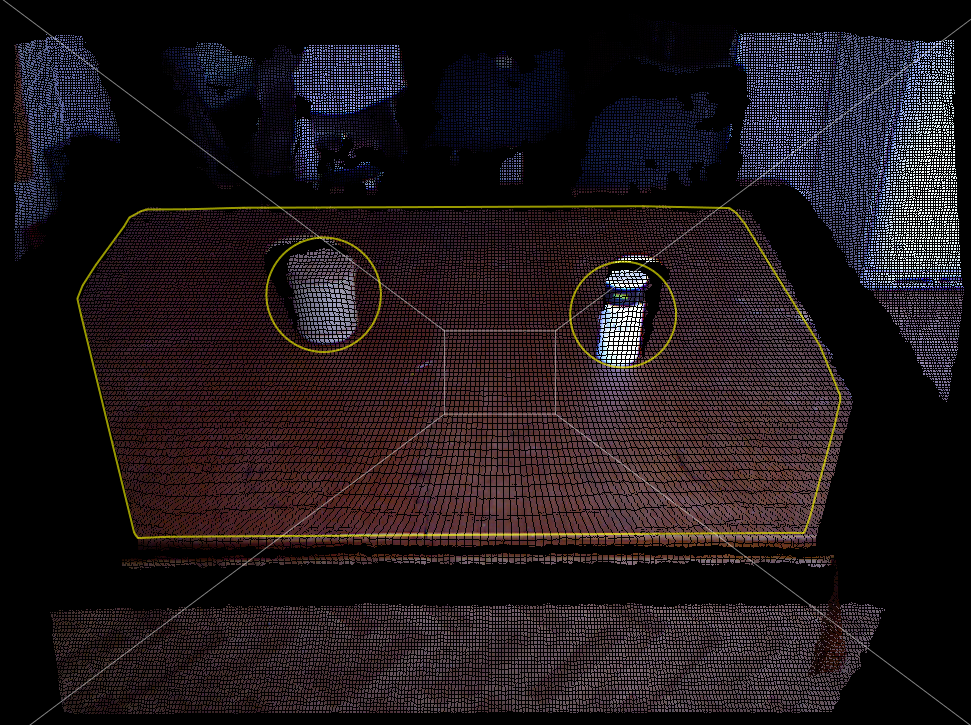

RGB and Depth Images - Depth in millimetres

Point Clouds

- The depth data can be manipulated to determine each point's 3D coordinate

- This forms a Point Cloud

The Algorithms

Need to convert the raw data into a usable form.

Then it is posible to detect the objects.

This requires the use of the following operations:

- Surface Normals

- Plane Segmentation

- Point Clustering

- Cluster Filtering

- Dominant Plane Detection

- RANSAC

- Convex Hull

- Point Inclusion

- Object Point Clustering - K-Means

Surface Normals

Calculate the surface normal of each 3D point

using neighbouring points.

Plane Segmentation

As mentioned previously, this contains many steps

- Point Clustering

- Cluster Filtering

- Dominant Plane Detection

- RANSAC

- Convex Hull

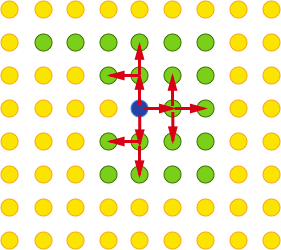

Point Clustering

Use Tags!

- Iterate through all points. For each:

- Does it already have a tag? Then go to the next point. Otherwise:

- Give this point a new tag

- For each of the neighbouring points:

- Determine the angular difference using surface normals

- If the difference is within a threshold then this point is given the same tag as the original and is pushed to the queue

Now each point has a tag

Cluster Filtering

Now filter out tags that don't represent a plane

- First count how many points belong to each tag

- Add each point to its relevant tag cluster

- Filter out all the clusters below a given point count threshold

Dominant Plane Finding

Which plane cluster is the table?

- Determine the confidence of each cluster

- Based on point count, and

- Centroid (relative to camera)

- The cluster with the highest confidence must be the table

NB: This assumes that there is a table

The RANSAC Algorithm

RANdom Sample And Consensus

- This algorithm allows a fast approximation of a desired value

- In this case it is used to approximate the plane coefficients of the table

- How it works:

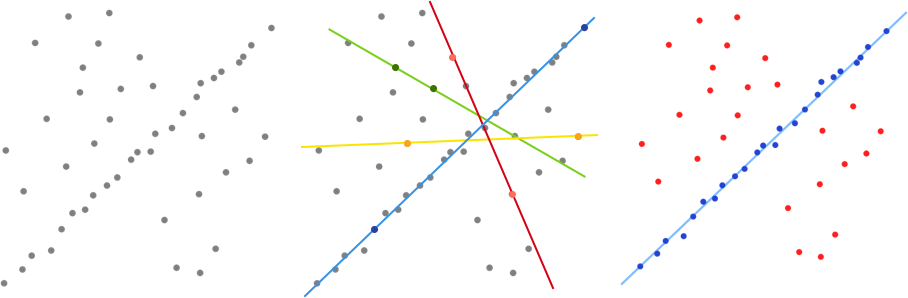

The Convex Hull Algorithm

- This algorithm will give the points that make up the edges of the table

- This allows for later processing of points that lie within and on the table

- How it works:

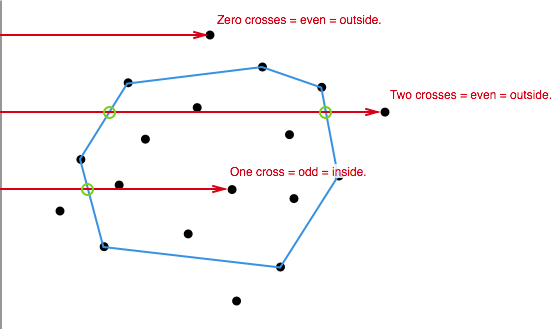

Point Inclusion

There is now a lot of information available:

- Table plane coefficients - from RANSAC

- Table plane bounds - from Convex Hull

- Table surface points - from Plane Clustering

Which points make up objects on the table?

Use a Point-In-Polygon algorithm

- Implemented using Point Inclusion in Polygon Test created by W. Randolf Franklin

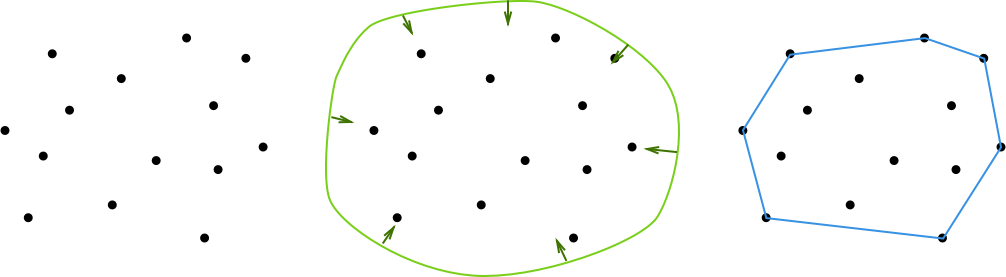

Object Point Clustering

- The final stage of processing

- Have a collection of 3D points representing all objects on the table

- Need to split up these points into individual objects

- Use the K-Means clustering algorithm

K-Means Algorithm

A process by which:

- All the points are spilt into 'k' groups

- Calculate the centroid of each group

- Determine the distance each point has from all of the centroids

- If the point is closer to another group rather than its own, move it to the other group

- Once there are no more movements of points, the clustering is finished

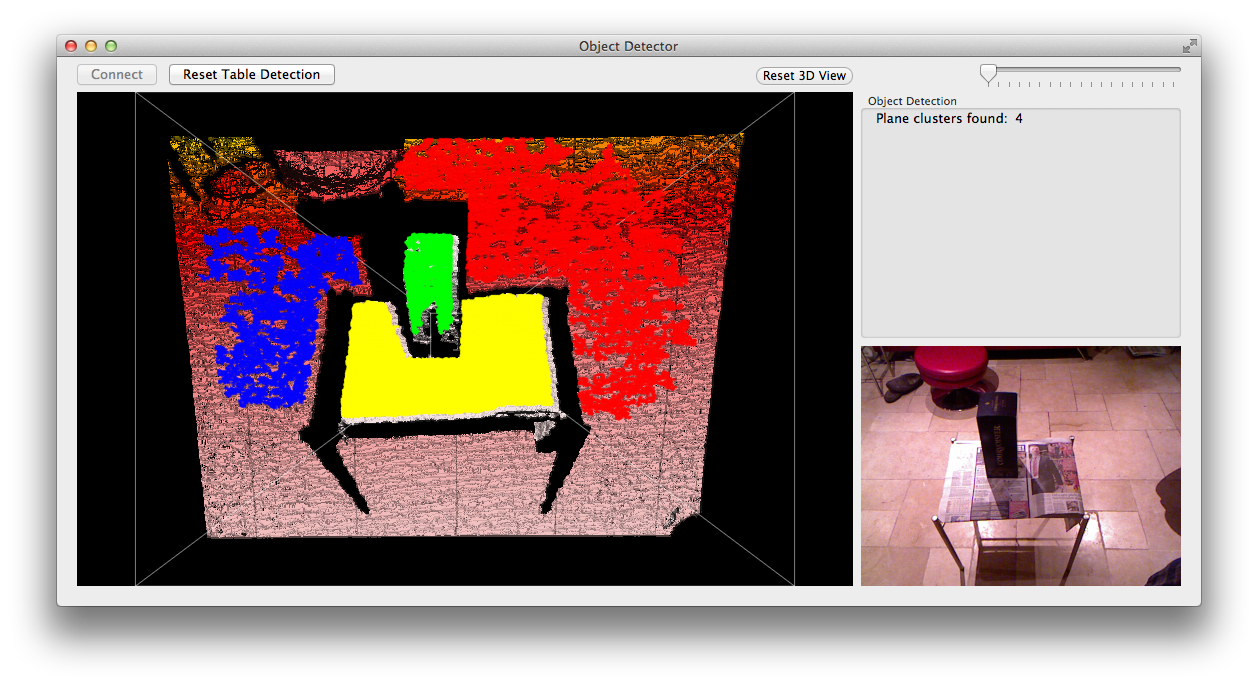

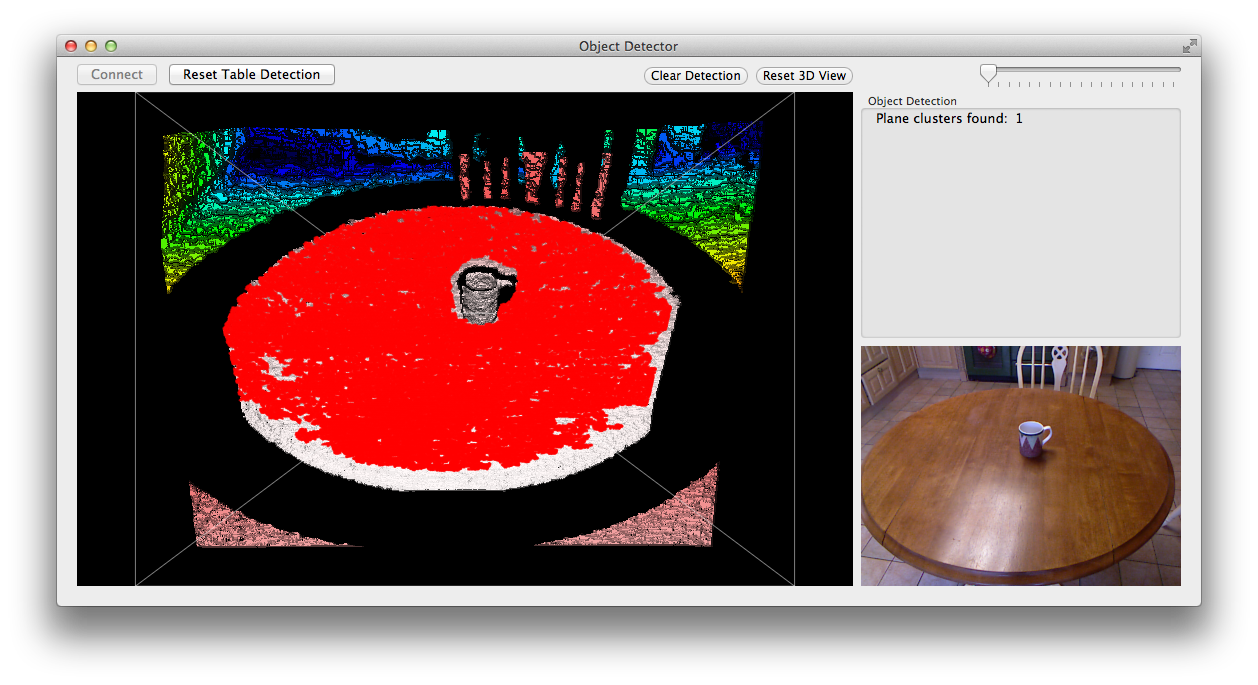

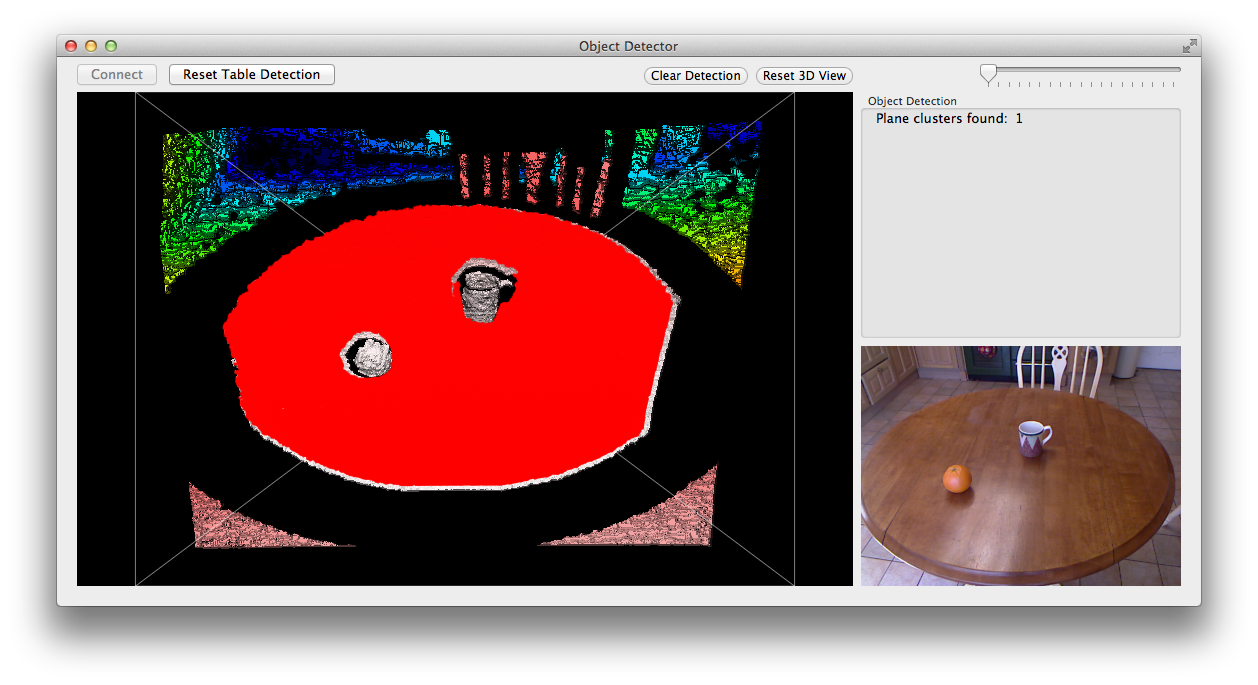

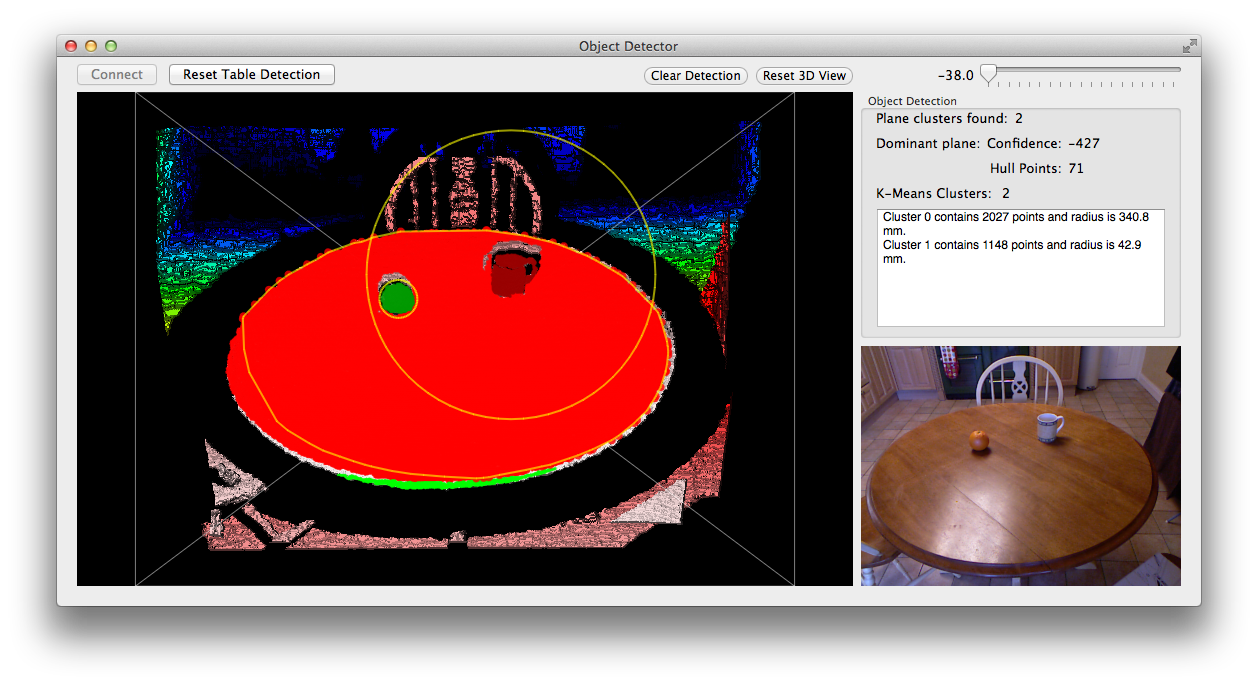

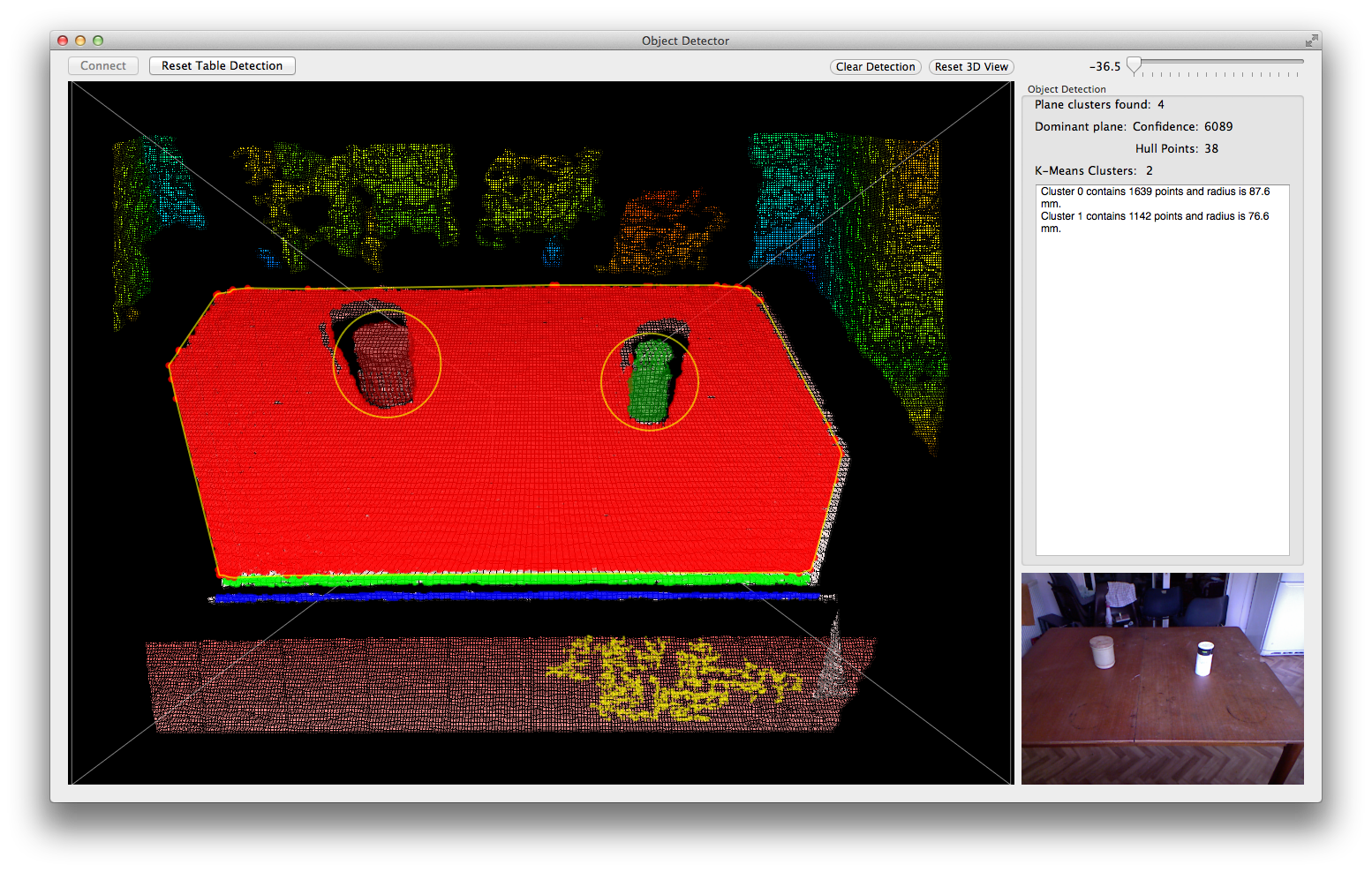

Results

Before Calibration

Some Calibration

After Calibration

With Object Detection

Extended Calibration

Improvements

- A major limitation is the 'k' in K-Means

- The number of objects must be known before computation

- An alternative is a method similar to plane point clustering

Future Work

- Shape Fitting

- Integration of eye-tracker information

- Communication with electronic system

- Reduced processing time

Project Execution

By Joe Ahuja

Overview

- Weekly meetings

- Online group

- File sharing group

- Conflict resolution

- Budget

- Project Timeline

Weekly Meetings

- Progress reports

- Forum for discussing issues

- Chance to work directly together

- Enabled overview of entire project

- Facilitates teamwork and bonding

Online Group

- Forum for group discussion

- Convenient platform for progress reports

- Communication with entire team

- Can demonstrate pictures and videos

- Enables contact at all times

File sharing group

- Is a repository for all files related to project

- Encourages transparency of work within the team

- Enables group contribution when not together

- Provides a record of all electronic work

Conflict Resolution

- Discussion encouraged between the two parties

- Quick action encouraged

- No third party has had to step in

- In this team resolution occurs organically through frank and honest discussion

Budget

- Project Budget- £600.00

- Project Spend- £476.72

- Project within budget

- Budget managed through file sharing group

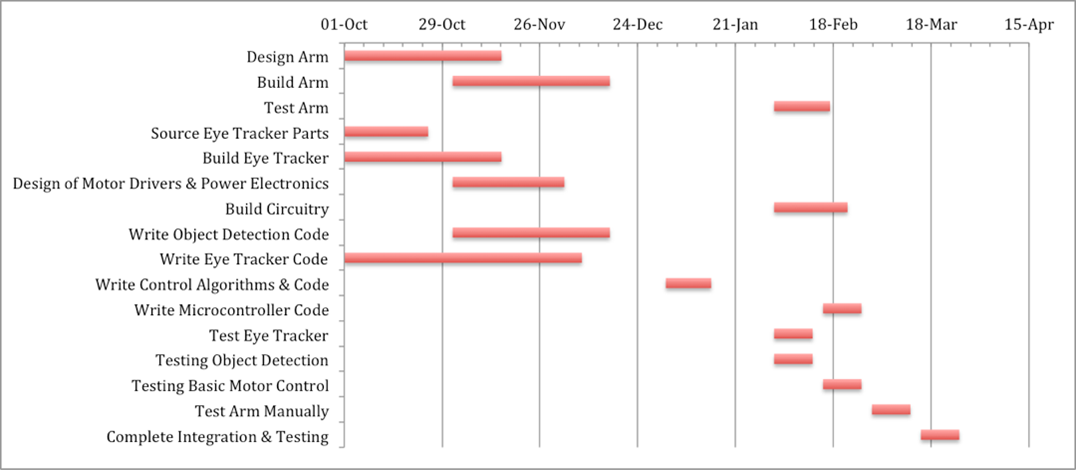

Project Timeline

- Significant changes due to delays in manufacture

- Compensated by working around the delay accomplishing as much as possible

Summary

- Weekly meetings - teamwork, discussion, progress reports, project overview

- Online group - record of communication, anytime communication, discussion

- File sharing group - transparency of work, group work, record of work

- Conflict resolution - self resolution encouraged, quick action encouraged, frank and honest discussion normally effective

- Budget - project completed within budget through file sharing management

- Project timeline - adhered to as much as possible

- Delays in manufacture were worked around as much as possible

- Team managed well through several means

- Facilitates cohesive group and project outcomes